Products

Product Characteristics

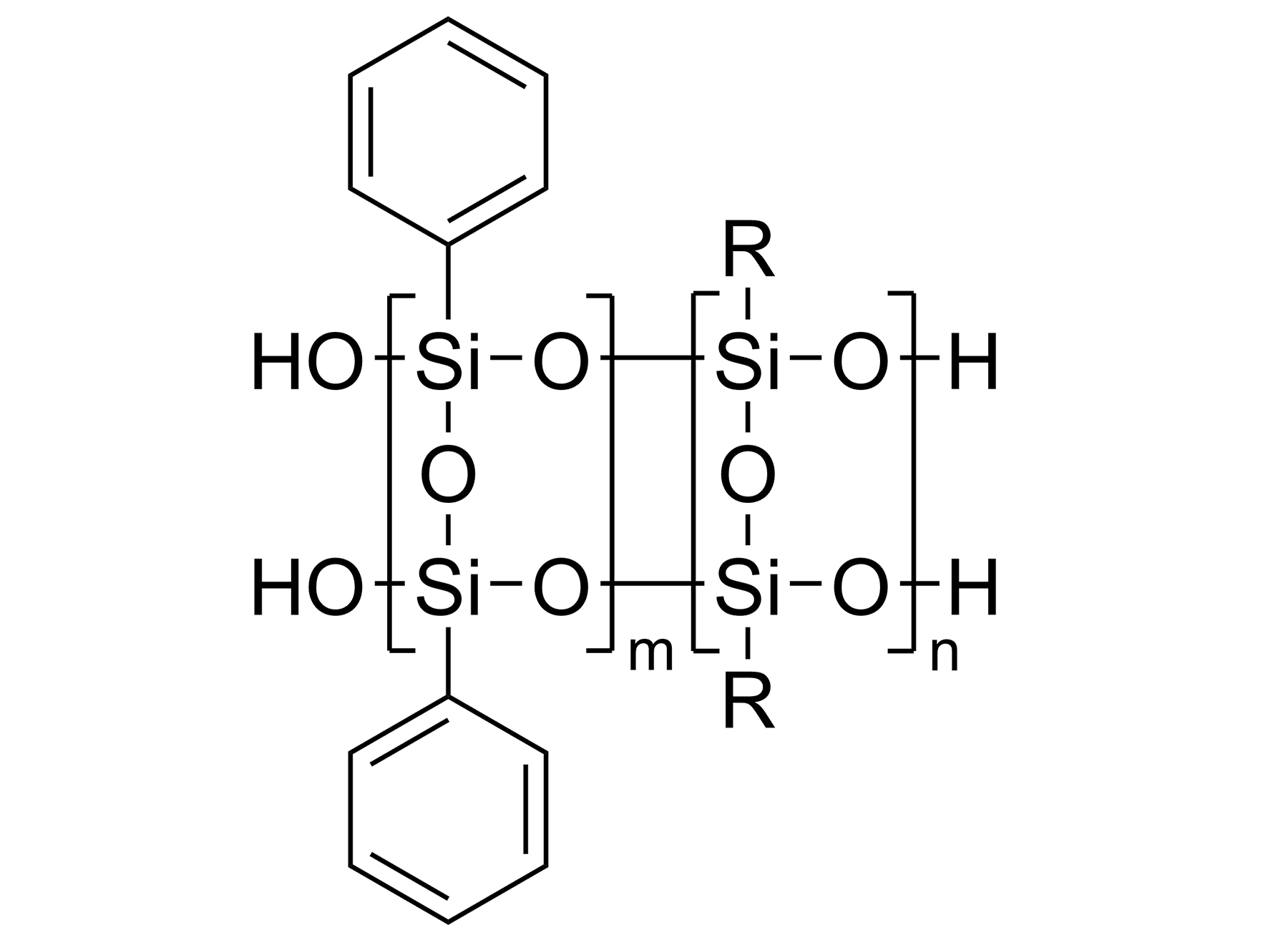

Cheersil 8568 phenyl silicone resin is a kind of organosilicon intermediate with silicon hydroxyl functional group and low molecular weight. It can react with acrylic resin, alkyd resin, phenolic resin, polyester resin, epoxy resin and other organic resins with hydroxyl group to realize the modification of organic resin, in order to further improve the stability and weatherability of organic resin. It is mainly used for curing, building coating and electrical appliance coating, coil coating, powder coating and high temperature coating.

The organic resin modified by Cheersil 8568 phenyl silicone resin is used for curing coating, coil coating and building coating, with excellent weather resistance, anti-embrittlement, anti-pulverization, and good luster and color brightness. It is used for high temperature coating, with excellent light and color retention, and can be used for high temperature equipment such as heater, oven, incinerator, etc. The operating temperature can reach 425 ℃ if use aluminum powder as filler pigment.

Typical Properties

|

Item |

Specifications |

|

|

Appearance |

Transparent sheet or particle solid |

|

|

Chroma (Pt-Co, 70% in MIBK) |

≤20 |

|

|

Density (25℃, g/cm3) |

1.25 |

|

|

Viscosity (25℃, mm2/s, 70% in MIBK) |

60~140 |

|

|

Volatile content (%) |

105℃/3hr |

≤3 |

|

250℃/3hr |

≤5 |

|

|

800℃/1hr |

45~50 |

|

|

Softening Point (℃) |

40 |

|

The typical property is not an indicator of the quality of the product.

Application

The modification of Cheersil 8568 organic resin by phenyl silicone resin is usually carried out by solvent method or melting method, and the copolymerization can be accelerated by titanates catalyst. Cheersil 8568 phenyl silicone resin can also be cold blended with a variety of organic resins, but its exothermic compatibility should be tested in advance before use.

Packaging and Storage

Safety and Transportation

The product should be sealed and stored at room temperature to avoid sun exposure, high temperature, pollution or water vapor entering. Cheersil 8568 phenyl silicone resin is not conductive but appropriate precautions should be taken because transportation may generate static electricity.

Customers should carefully read the product information, material safety data sheet (MSDS) and labels before use. And familiar with the product safety information, operating instructions, environmental impact, and wearing the appropriate personal protective equipment as required.